| Block_hintergrund |

| Block_zwischenhintergrund |

| Block_Hauptmenue |

| Block_Slider |

| Block_Zwischenhintergrund2 |

| Behälter_drehvorrichtungen |

Container turning devices

For turning and positioning workpieces

|

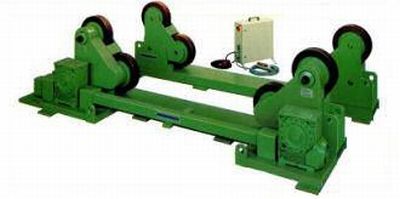

| Types RD 10 - RD 600 |

| ø min 800 - 2.000 mm ø max 3.500 - 7.000 mm |

| Load capacity: 10 to - 600 to |

|

| Types RC 40 - RC 300 |

| ø min 500 - 700 mm ø max 4.000 - 6.000 mm |

| Load capacity: 40 to - 300 to |

|

| Types RB 20 - RB 1000 |

| ø min 400 - 600 mm ø max 3.500 - 6.000 mm |

| Load capacity: 20 to - 1000 to |

|

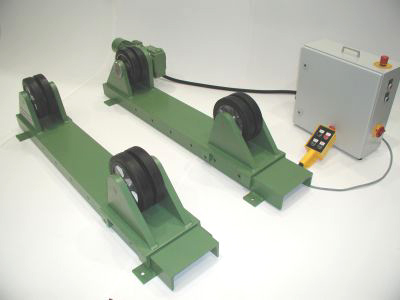

| Types RA 3 - RA 30 |

| ø min 100 - 500 mm ø max 2.500 - 4.500 mm |

| Laod capacity: 3 to - 30 to |

|

| Types RL 1,5 - RL 10 |

| ø min 50 - 100 mm ø max 2.000 - 3.500 mm |

| Load capacity: 1,5 to - 10 to |

HEINRICHSGLÜCK turning devices are very stable and built for continuous operation. In addition, they are safe to operate and correspondingly powerful.

The container turning device programme includes the type series as above:

RL: with single-roller drive, locking pin.

RB: with two-roller drive, screw locking.

RC: with two-roller drive, spindle adjustment.

RD: with four-roller drive, self-adjustment.

The base frames and roller stands are made of quality steel in torsion-resistant welded construction. The roller support swivel arms of the RD are fixed and self-adjusting. On the other models, the roller blocks are movable and are fitted with a locking pin as standard.

The castors are made of steel or have rubber or Vulkollan pads.

The rollers in the roller blocks are evenly driven directly by one or, depending on the model, two or more three-phase drives.

Frequency converters provide stepless control and a good constancy of the rotation speed. The regulating and control devices are housed in a separately erectable sheet steel control cabinet. The rotation speed is set with the potentiometer on the control cabinet.

Remote control alternatives:

Hand switch, foot switch or switch in the welding shield.

In addition to welding, rotary fixtures can also be used for grinding, polishing, cleaning, blasting, coating, drilling, milling, testing, drying, stirring, mixing and filtering, if designed accordingly.

Special versions:

Trolleys with or without drive, movable roller blocks via spindle manually or motorised, roller design as a combination of steel-polyurethane, polyamide or rubber, even larger dimensions due to larger workpiece diameters, one or two outer rollers for widening the support, start-up rollers, etc.

Additional control for integration in unit carrier controls, controller with control range up to 1:200 with high speed constancy, two or more tracking units to one drive unit for particularly long workpieces, parallel connection of several drive units.

Other special designs are possible on customer request.

| Aktuelles |

New series of turning devices

DT 0.1-0.2

According to this motto, a new series, the DT 0,1-0,2, was developed in close cooperation with our customers

read more...

------------------------------------------------------

| Block_Uebersicht_1 |

| Block_Uebersicht_2 |

| Block_Logo_Uebersicht |

| Block_Fusszeile1 |

| Block_Fusszeile2 |

© HEINRICHSGLÜCK 59494 Soest

| Block_Fusszeile3 |